PDR tools, advanced devices for dent removal without painting, use air compressor and vacuum systems along with diverse tips. Regular maintenance includes cleaning, lubrication, part replacement, and proper storage to ensure optimal performance. Disinfection is crucial for hygiene and preventing cross-contamination. Correct storage, avoiding moisture and extreme temps, extends tool lifespan and enhances efficiency in car paint services.

In the realm of automotive aesthetics, Paintless Dent Repair (PDR) has emerged as a game-changer. This non-invasive technique preserves vehicle paintwork, making it a popular choice for professionals and DIY enthusiasts alike. To ensure optimal performance and longevity of your PDR tools, proper maintenance is paramount. From understanding tool functionality to implementing regular cleaning routines and secure storage practices, this guide offers essential tips to keep your PDR equipment in top condition.

- Understanding PDR Tool Functionality and Parts

- Regular Cleaning and Disinfection Procedures

- Proper Storage for Optimal Lifespan Preservation

Understanding PDR Tool Functionality and Parts

Understanding PDR Tool Functionality and Parts

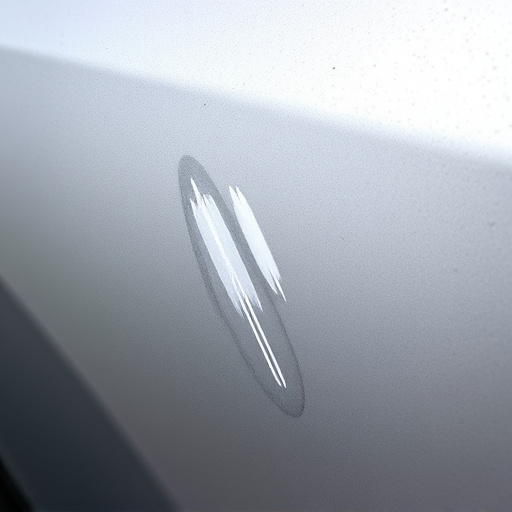

PDR (paintless dent repair) tools are designed to restore car bodies without the need for traditional painting or filling. These innovative devices use specialized technology to remove dents, making them a go-to option in collision repair shops. The primary functionality lies in their ability to mimic the natural flexibility of metal, allowing them to push out and conform to the dent’s shape.

Each PDR tool consists of several key parts: an air compressor, a vacuum system, and various tips or attachments. The air compressor provides the necessary force, while the vacuum system ensures precise control. Tips come in different sizes and shapes, catering to various dent sizes and angles, much like how a skilled Mercedes-Benz repair technician might use specific tools for car body restoration. Regular maintenance involves keeping these components clean and well-lubricated, replacing worn-out parts promptly, and storing tools properly to prevent damage or misalignment.

Regular Cleaning and Disinfection Procedures

Regular cleaning and disinfection are essential practices for maintaining optimal PDR (paintless dent repair) tools hygiene and efficiency. After each use, it’s crucial to thoroughly wipe down all equipment with a suitable cleaner to remove any debris or remnants of the repaired vehicle’s surface. This prevents buildup and ensures the tools remain in top condition.

Disinfection is equally vital, especially when dealing with various vehicles and clients. Using automotive-grade disinfectants, clean all tools, including pads, guns, and applicators, to kill bacteria and viruses. This not only protects the technician but also prevents cross-contamination between different vehicle repair services or automotive body shop jobs, making it a standard procedure in any professional fleet repair service.

Proper Storage for Optimal Lifespan Preservation

Proper storage is an often-overlooked aspect when it comes to maintaining PDR tools, yet it plays a pivotal role in ensuring their longevity and optimal performance. After each use, it’s crucial to store your PDR tools carefully, especially if they are high-quality, professional-grade equipment. Invest in a sturdy, dedicated storage case or rack that keeps tools organized and protected from potential damage. Avoid stacking tools haphazardly, as this can lead to nicks, scratches, or even deformity over time.

Consider the environmental conditions as well. Ensure your storage area is clean, dry, and free from extreme temperatures. Moisture and direct sunlight can accelerate tool corrosion and degradation of sensitive components. By implementing these simple storage practices, you’ll significantly contribute to the lifespan preservation of your PDR tools, ultimately enhancing the efficiency of car paint services or vehicle paint repair processes that rely on them.

Maintaining your PDR tools properly is essential for ensuring their longevity and maximizing their effectiveness in paintless dent repair. By following these simple maintenance and care tips, including regular cleaning, disinfection, and secure storage, you can keep your PDR tools in top condition, enabling efficient and reliable dent removal for years to come.